Distillers are turning to speciality malts in distilling to try and differentiate their products. There has been some research and experimentation with yeast strains and even bacteria. To try and draw on the knowledge from the craft beer and wine-making world into distilling. Speciality malts open up a new world of flavours that can be carried into different spirits.

Whiskey Production using speciality malts – caramel & roasted malts can contribute to flavour.

Whiskey production and the demand for whiskey are at unprecedented levels. With large-scale investment being put into existing distillers and the emergence of many new distilleries coming into the market. Historically whiskey flavour could be enhanced with the use of wooden barrels during the ageing process. Recently, we have seen the distilleries locally in Ireland use ex-stout casks to impart flavour. Distillers have been using different oak varieties from different parts of the world. The barrels also have different charring levels and use smaller barrels to impart flavour more quickly.

Spirit flavours are an essential part of the distillation process also. Barrels and ageing bring flavours that have an enormous impact on flavour when the distiller makes the cut of the heads, hearts and tails. This is where the distiller’s skill kicks in, knowing when to cut. Pot stills impart more flavours. The esters in the copper impart flavour into the spirit as it travels through the distillation process. The purity of the spirit can be improved with extra distillation runs.

Distilling Equipment

The type of distilling equipment will have an effect on flavour. Also, some are a mixture of steel and copper, and some have wooden washbacks as opposed to stainless steel. Some distilleries use a cooker for the mash and transfer all of the mash into the fermenter and subsequently onto the still. This produces a pronounced grain, bready and nutty flavour. Opposed to the fruitier finish of a mash that has been separated.

If you are interested in the malting process, we have two videos on our youtube channel: Behind the scenes at Dingemans Malting and Crisp Maltings Tour. This gives an insight into the malting process from Barley intake through Steeping, Germination, Kilning & Roasting.

When distilling with speciality malts, the mixture of your base grain can incorporate caramel and roasted malts to achieve new flavours. Brewers use low quantities of these speciality malts in their grist range of approximately 20-30%. Speciality malts tend to have less diastatic power and fermentable sugars than base malt. So that needs to be considered when compiling the base mixture of malts. You can use an HDP malt to offset this. The flavour from speciality malt carries through beautifully into the finished spirit.

The Maillard reaction

The Maillard reaction ( the chemical reaction between amino acids and reducing sugars ) that occurs during the roasting process creates some complex and distinct flavours. If processed at higher temperatures, we get caramelisation reactions. However, it does reach an upper limit that we can go with the roasted malt. This upper limit is malted like Chocolate, Black & Roasted Barley. We don’t want to go above 230 degrees Celcius as that will cause the malt to burn.

Distilling with speciality malts

Speciality malts contain roasted-flavour aroma compounds, which form during high-temperature kilning or roasting. In high temperatures, Maillard and caramelisation reactions produce desirable flavour molecules in malt, like pyrazines and furans. These compounds are extracted from malt during mashing and then travel all the way to the spirit and, eventually, whisky.

These provide some beautifully attractive aromas. The mash made from darker grains will be more acidic. The fermentability will be reduced but getting the percentage of speciality malts is key to achieving those aromas and flavours. This flavour from the speciality malts can definitely be carried into the spirit. Flavour volatiles provides chocolate, nutty and coffee-like aromas.

What are pyrazines and furans?

They are aromatic, organic, low molecular weight and volatile compounds. There are a few differences between them, such as pyrazines contain nitrogen, and furans don’t. Pyrazines are formed during roasting (>140C). Whereas furans form during kilning and roasting. The most incredible abundance of flavour-active pyrazines was found in malt roasted at 150-175. Whereas furans were at 185-220 degrees*. *Data from Heriot Watt – Rutele Marciulionyte

(Big thanks to Rutele Marciulionyte for helping us to correct some of the information)

Points of note

Using a high quantity of roasted malts in the base grain may cause runoff issues in the mash. You can look at adding Rice Hulls to assist with giving the grain bed filterability. The variety difference of malt is also an exciting area for distillation. For example, Floor Malted Maris Otter & Other Heritage Malts. As we learn and experiment more with speciality malts and the temperature and time we roast them, we are sure that Heritage malt varieties will bring some complex and interesting flavours.

The regulatory framework for the production of whiskey for the region, for example, Irish & Scorch whiskey, limits being able to add flavouring, so the flavours need to come from the ingredients and the ageing process, and as demand for complex flavours grows, its an exciting time for distillers to be able to experiment with malts and yeasts.

Creating flavours within raw materials is possible with the beautiful range of speciality malts that we stock from Crisp Maltings & Dingemans Malt. A local example would be Bushmills distillery using crystal malt in their causeway special release and many new make projects now ongoing which are still to be released.

The sensory experience from some of the Belgian Speciality Malts is really captivating when we taste and smell the malt in the warehouse with unique varieties like Chocolate Rye and Amber Aromatic Malt. We also stock the full catalogue of Crisp Malt products including Premium Potstill, Peated Potstill & HDP Malt so we have the entire catalogue of malts for distillers.

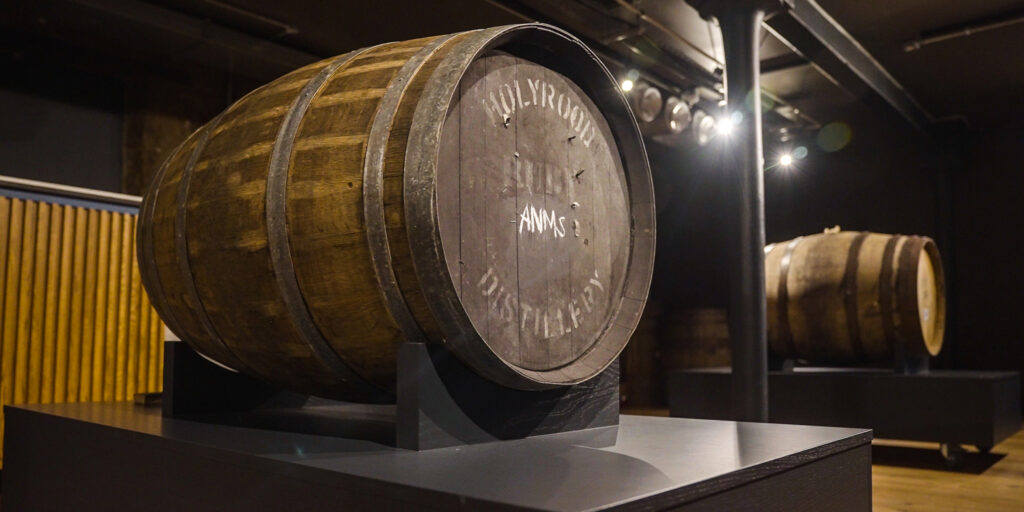

Checkout our video at Holyrood Distillery who are pioneering this new process: